Budwig Molded Products

Budwig Company Inc. has been designing and manufacturing proprietary injection molded thermoplastic products since 1965. We are not a distributor and only sell what we manufacture at our San Diego, California facility.

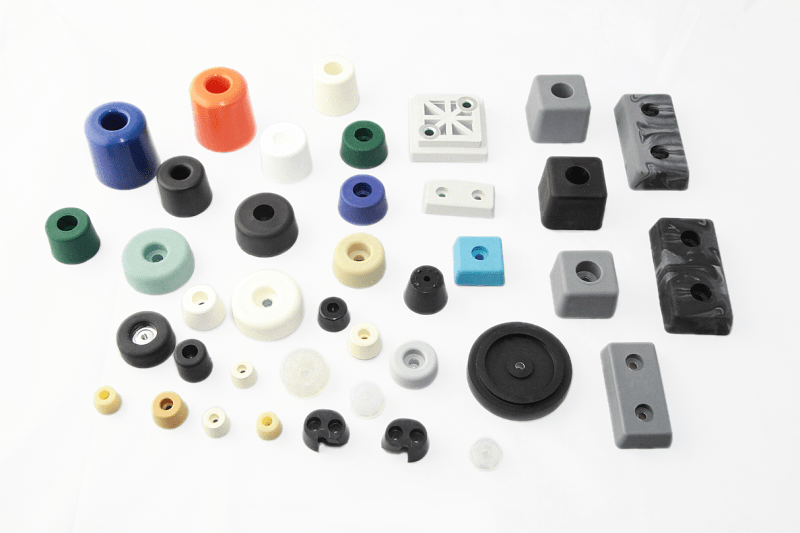

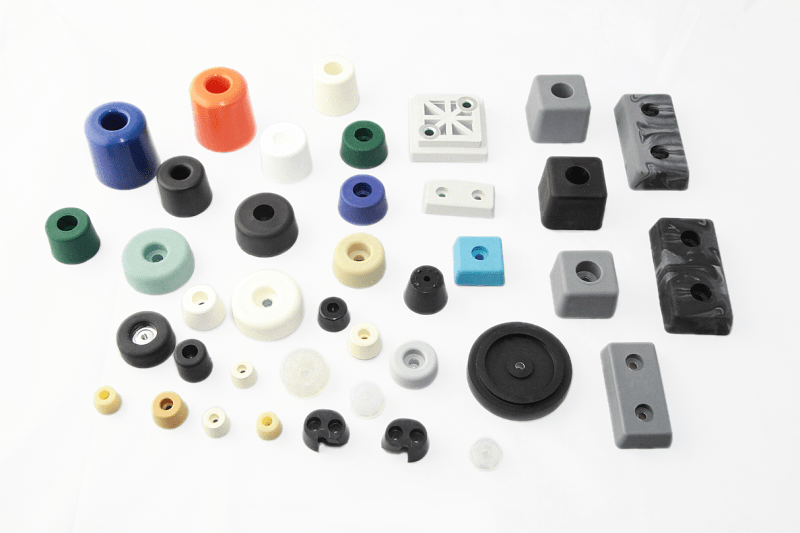

Plastic/Rubber Feet & Bumpers

Our product line includes: Rubber feet, collapsible tilt stands, cable straps, antenna connectors and insulators used by ham radio operators to build di-pole antennas. When it comes to Plastic Feet and Rubber Bumpers, no other company offers higher quality bumpers at affordable prices as offered by Budwig and is a premier manufacturer of Rubber Bumpers also known as Bumper Feet.

Although most of our products were developed for the electronics industry they are used extensively in various other applications and industries. Budwig bumpers (feet) are manufactured by using ‘Santoprene’ thermoplastic rubber.

Thermoplastic Rubber Feet - Standard Injection Molded Plastic Feet and Bumpers offered by Budwig.

Rubber Feet, we injection mold them in over thirty sizes. We mold other materials but thermoplastic rubber feet has become our first choice. We stock them in black and medium grey and offer optional colors and hardness. View all Rubber Feet molded products, Round, Square, Rectangular - in any color available from Budwig.

If you don't find what you need from our existing product line, we can use your design or we will custom design one for you. Along with our other products we keep over two million pieces of inventory to provide off-the-shelf delivery. We will be happy to send you free samples to test or compare. We believe you will find our products to be an excellent balance of quality, performance and price.

We are an Original Equipment Manufacturer (O.E.M.). We only sell what we manufacture at our facility in San Diego, California.

Virco Uses Rubber Feet on Various Products

Virco Uses Rubber Feet on Various Products Headquarted in Torrance, California, Virco has been a longtime supplier of school furniture and equipment. From supplying K-12 to community colleges and four year universities, Virco has been a leading name in the industry. Their products remain an example of the high quality…

Rubber Bumper Feet on PA Boards and Consoles

Budwig Custom Molding – Rubber Bumpers

Dressers and Chests use Rubber Feet for Stability

Few storage units are as versatile, sturdy, and stylish as chests & bases. Particularly in the USA, chests are a specific craft that are distinguished by their superiority and sleek design. Rubber feet, least of all, shouldn’t be sidelined when making such useful pieces of furniture. H. Gerstner & Sons,…

Commercial furniture can always benefit from high quality rubber bumpers.

Commercial furniture can always benefit from high quality rubber bumpers. Whether the chairs, desks, and tables are being placed in conference rooms or lobbies, Budwig’s rubber feet are built-to-last and won’t crack or crumble. The office environment is important for functionality, productivity and safety of the staff. Rubber bumpers offer…

Will Your Product Be Next Year’s “It” Item?

Do You Need American-Made Plastic Bumper Feet?

Over the past few years, the business news have been featuring stories about large companies like Burger King, Budweiser, and many others fleeing overseas or performing complicated inversion deals to avoid U.S. taxes. These moves have left a sour taste in the mouth of many Americans and a renewed interest…

Industries that use Rubber Bumpers

Rubber bumpers find applications across various industries due to their versatility, durability, and ability to absorb impact. Here are several industries that commonly use rubber bumpers: Automotive Industry: Rubber bumpers are used in vehicles for various purposes, such as door bumpers, bumper stops, and as components in suspension systems to…

Square Feet

Like all of the products in our catalog, Budwig’s square feet are available in many sizes and varying hardness to fit whatever merchandise that needs protection and mark resistance. Similar to rectangular feet, Budwig Company’s square feet are angled to streamline sharp corners on machines or devices. With continuous temperature…

Furniture Rubber Feet

Furniture is a mainstay of any home or office and provides comfort, practicality, or both. However if it doesn’t have proper bottom-end support, couches, bed frames, tables, and cabinets will quickly deteriorate. While it can be tempting to cut costs on the underbelly of your movables, it often times hurts…

Budwig Company

Budwig Company Inc. has been designing and manufacturing proprietary injection molded thermoplastic products since 1965. We are not a distributor and only sell what we manufacture at our San Diego, California facility.

Specialty - Rubber Bumpers

Budwig specializes in TPR (thermoplastic rubber) rubber bumpers, which are used in a variety of applications in the electronics, security, medical, and consumer products and more. Budwig rubber bumpers are available in various shapes & sizes.

Facility Capabilities

Being a plastic product development and marketing facility we have the capacity to perform almost all requirements in-house: Product design, mold making, injection molding, assembly, testing and packaging. Give us a call for your project needs.