Budwig Molded Products

Budwig Company Inc. has been designing and manufacturing proprietary injection molded thermoplastic products since 1965. We are not a distributor and only sell what we manufacture at our San Diego, California facility.

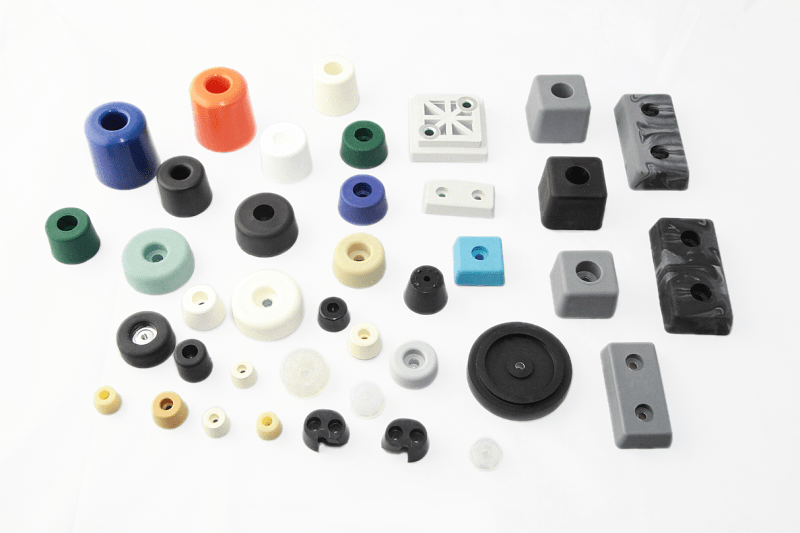

Plastic/Rubber Feet & Bumpers

Our product line includes: Rubber feet, collapsible tilt stands, cable straps, antenna connectors and insulators used by ham radio operators to build di-pole antennas. When it comes to Plastic Feet and Rubber Bumpers, no other company offers higher quality bumpers at affordable prices as offered by Budwig and is a premier manufacturer of Rubber Bumpers also known as Bumper Feet.

Although most of our products were developed for the electronics industry they are used extensively in various other applications and industries. Budwig bumpers (feet) are manufactured by using ‘Santoprene’ thermoplastic rubber.

Thermoplastic Rubber Feet - Standard Injection Molded Plastic Feet and Bumpers offered by Budwig.

Rubber Feet, we injection mold them in over thirty sizes. We mold other materials but thermoplastic rubber feet has become our first choice. We stock them in black and medium grey and offer optional colors and hardness. View all Rubber Feet molded products, Round, Square, Rectangular - in any color available from Budwig.

If you don't find what you need from our existing product line, we can use your design or we will custom design one for you. Along with our other products we keep over two million pieces of inventory to provide off-the-shelf delivery. We will be happy to send you free samples to test or compare. We believe you will find our products to be an excellent balance of quality, performance and price.

We are an Original Equipment Manufacturer (O.E.M.). We only sell what we manufacture at our facility in San Diego, California.

How Rubber Bumpers Protect Products and Extend Equipment Life

Small components often make a big difference in product durability and performance. One of the most important but frequently overlooked components in product design is the rubber bumper. High-quality rubber bumpers provide protection, stability, and vibration control across many industries—from electronics and appliances to furniture and industrial equipment. Companies designing…

Square Rubber Feet vs. Round Rubber Feet: Choosing the Right Option for Your Application

Selecting the correct rubber feet for a product is essential to ensuring stability, safety, and long-term performance. While round rubber feet are commonly used, square rubber feet offer distinct advantages in applications where enhanced grip, alignment, and load distribution are required. Square rubber feet provide increased surface contact compared to…

Commitment to Quality Manufacturing Rubber Bumpers

Budwig has been serving the manufacturing industry for over 50 years. Since the company’s inception, Budwig has been dedicated to producing top quality products at competitive pricing. All of our products are proudly made in the USA and at no point have our products’ integrity been compromised with subpar materials…

Why Round Rubber Feet Are Essential for Product Stability and Protection

Round rubber feet play a critical role in protecting products, improving stability, and reducing vibration across countless applications. From consumer electronics to industrial equipment, these small but powerful components help extend product life while improving performance and safety. One of the primary benefits of round rubber feet is their ability…

Prepare Your Patio Furniture for Spring and Summer With High-Quality Rubber Bumpers

With spring and summer right around the corner, it’s the perfect time to get your outdoor spaces ready for warm weather gatherings, relaxed evenings, and backyard entertaining. As you clean, repair, and upgrade your patio furniture, one detail that should never be overlooked is the quality of the rubber bumpers…

The New Tsunami Pre-Amp V-15 Uses Rubber Feet

When Keith Stixx was searching for the right rubber feet for his new bass pre-amp, performance was the top priority. Bass equipment produces significant vibration and low-frequency rumble, and without proper isolation, those vibrations can interfere with sound quality, component stability, and long-term durability. To solve this challenge, Keith reached…

Bar Stools With Rubber Bumpers for Balance

Bar stools are a stylish and functional accent in restaurants, bars, cafés, and modern living spaces. They provide seating while helping define the overall aesthetic of a space, whether the look is industrial, contemporary, or classic. However, one often-overlooked detail can significantly affect both appearance and performance: the rubber feet…

F-Series Rubber Bumpers are Used for Heavy-Duty Applications

Collapsible Tilt Stands: Durable, Reliable, and Made in the USA

While Budwig is widely recognized for manufacturing high-quality recessed rubber bumpers, our product line extends far beyond protective feet. We also produce durable collapsible tilt stands and cable straps—versatile accessories designed to provide stable support for electronic equipment of all types. These stands are especially popular for ham radios, communication…

Commercial furniture can always benefit from high quality rubber bumpers.

In any commercial environment—whether it’s a corporate office, hotel lobby, medical facility, educational campus, or government building—furniture must be durable, stable, and built to withstand heavy, everyday use. One often-overlooked component that significantly improves longevity and performance is the rubber bumper. At Budwig, we specialize in manufacturing premium rubber feet…

Budwig Company

Budwig Company Inc. has been designing and manufacturing proprietary injection molded thermoplastic products since 1965. We are not a distributor and only sell what we manufacture at our San Diego, California facility.

Specialty - Rubber Bumpers

Budwig specializes in TPR (thermoplastic rubber) rubber bumpers, which are used in a variety of applications in the electronics, security, medical, and consumer products and more. Budwig rubber bumpers are available in various shapes & sizes.

Facility Capabilities

Being a plastic product development and marketing facility we have the capacity to perform almost all requirements in-house: Product design, mold making, injection molding, assembly, testing and packaging. Give us a call for your project needs.

We sell only what we manufacture at our facility in San Diego, California.

We sell only what we manufacture at our facility in San Diego, California.