Rectangular Thermoplastic Rubber Feet with Steel Support Bushing

Molded from “Thermoplastic Rubber” Budwig recessed bumpers provide good traction and excellent shock absorbing qualities; unlike natural rubber they have good non-marking qualities and outstanding resistance to stress cracking. A Trivalent Chromate plated steel Support Bushing (S/B) absorbs the total fastener load allowing the foot to be mounted using a variety of screws or rivets without causing distortion to the foot itself. Excellent resistance to ozone, aging and most chemicals. Available in any color on special order. *Some sizes available in Polyethylene or Polypropylene as an alternative to Thermoplastic Rubber. Recommended where resistance to sliding and shock absorbing or other rubber like qualities are not a requirement. Contact our sales staff for specific sizes that are available in Polyethylene or Polypropylene material.

Stock Material: Santoprene™ (87 shore A)

Stock Colors: Black or Medium Grey

Parts are BPA Free, 3TG, REACH and RoHS 3 Compliant

Click The Part Number to download the detailed Drawing and Specifications in a printable PDF

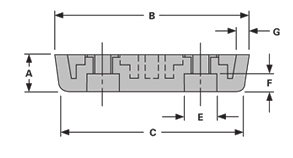

| PART NUMBER | Height A |

Length B |

Length C |

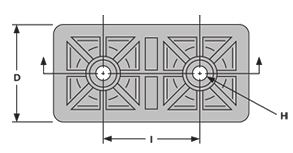

Width D |

Recess Dia E |

Recess Depth F |

Outer Wall Thickness G |

Insert I.D. & Screw Size H |

Mounting Hole Centers I |

No S/B Through Hole I.D. H |

|---|---|---|---|---|---|---|---|---|---|---|

| RF6T | .344 | 1.768 | 1.672 | .885 | .333 | .142 | .095 | .148 #6 Truss Head | .875 | .172 |

| RF6-1T | .390 | 2.022 | 1.912 | 1.005 | .333 | .187 | .125 | .148 #6 Truss Head | 1.000 | .172 |

| RF8T | .465 | 2.380 | 2.250 | 1.187 | .409 | .176 | .142 | .178 #8 Truss Head | 1.187 | .210 |

| RF10T | .528 | 2.777 | 2.629 | 1.375 | .472 | .202 | .172 | .215 #10 Truss Head | 1.375 | .255 |

| RF10-1T | .590 | 3.000 | 2.834 | 1.510 | .472 | .280 | .190 | .215 #10 Truss Head | 1.500 | .255 |

Tolerance: = ± .010

Weight Capacity:

Conclusive determination should be based on individual product testing and evaluation on a case by case basis by the end user. Factors such as; Durometer; the total number of feet (bumpers) being used; the environment (i.e. exposure to ozone, chemicals, extreme temperatures), static vs. dynamic applications, abrasion and shock should be considered and not limited to, for your final assessment.

We sell only what we manufacture at our facility in San Diego, California.

We sell only what we manufacture at our facility in San Diego, California.