Budwig Molded Products

Budwig Company Inc. has been designing and manufacturing proprietary injection molded thermoplastic products since 1965. We are not a distributor and only sell what we manufacture at our San Diego, California facility.

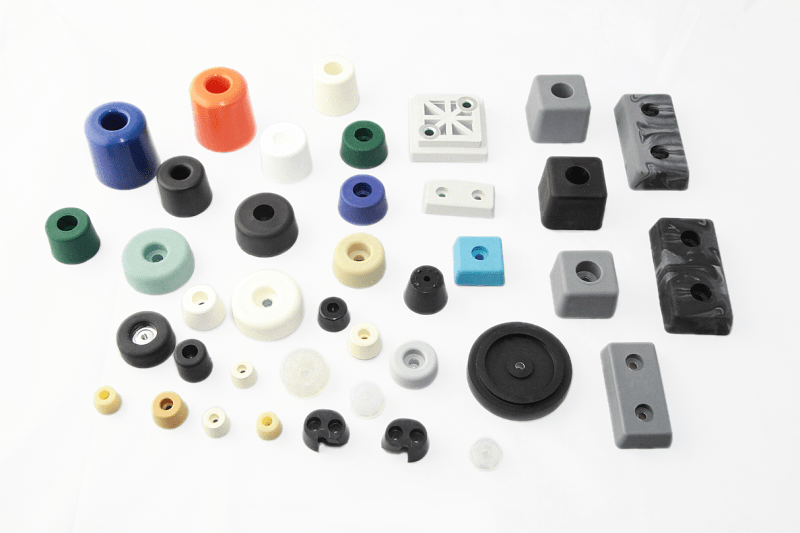

Plastic/Rubber Feet & Bumpers

Our product line includes: Rubber feet, collapsible tilt stands, cable straps, antenna connectors and insulators used by ham radio operators to build di-pole antennas. When it comes to Plastic Feet and Rubber Bumpers, no other company offers higher quality bumpers at affordable prices as offered by Budwig and is a premier manufacturer of Rubber Bumpers also known as Bumper Feet.

Although most of our products were developed for the electronics industry they are used extensively in various other applications and industries. Budwig bumpers (feet) are manufactured by using ‘Santoprene’ thermoplastic rubber.

Thermoplastic Rubber Feet - Standard Injection Molded Plastic Feet and Bumpers offered by Budwig.

Rubber Feet, we injection mold them in over thirty sizes. We mold other materials but thermoplastic rubber feet has become our first choice. We stock them in black and medium grey and offer optional colors and hardness. View all Rubber Feet molded products, Round, Square, Rectangular - in any color available from Budwig.

If you don't find what you need from our existing product line, we can use your design or we will custom design one for you. Along with our other products we keep over two million pieces of inventory to provide off-the-shelf delivery. We will be happy to send you free samples to test or compare. We believe you will find our products to be an excellent balance of quality, performance and price.

We are an Original Equipment Manufacturer (O.E.M.). We only sell what we manufacture at our facility in San Diego, California.

Collapsible Tilt Stands: Durable, Reliable, and Made in the USA

While Budwig is widely recognized for manufacturing high-quality recessed rubber bumpers, our product line extends far beyond protective feet. We also produce durable collapsible tilt stands and cable straps—versatile accessories designed to provide stable support for electronic equipment of all types. These stands are especially popular for ham radios, communication…

Commercial furniture can always benefit from high quality rubber bumpers.

In any commercial environment—whether it’s a corporate office, hotel lobby, medical facility, educational campus, or government building—furniture must be durable, stable, and built to withstand heavy, everyday use. One often-overlooked component that significantly improves longevity and performance is the rubber bumper. At Budwig, we specialize in manufacturing premium rubber feet…

Why Quality Rubber Feet Matter for Chests & Bases in American Craftsmanship

Few storage units offer the same blend of versatility, durability, and visual appeal as expertly crafted chests and bases. Whether used for tools, collectibles, sewing supplies, fine instruments, or keepsakes, these pieces are built to last and designed to be passed down through generations. In the United States especially, chests…

Industries That Rely on Rubber Bumpers for Protection and Performance

Rubber bumpers are essential components across numerous industries due to their durability, versatility, and ability to absorb impact and vibration. From protecting delicate electronics to reducing wear on heavy machinery, rubber bumpers play a critical role in improving safety, extending equipment life, and enhancing overall performance. Their wide range of…

Rubber Bumpers for Lamp Safety

Lamps do more than illuminate a space—they add warmth, atmosphere, and personality to homes, offices, hotels, and commercial environments. But even the most thoughtfully designed lamps can become unstable or damaged when they rely on low-quality or poorly fitted rubber bumpers. This is where Budwig’s premium line of recessed rubber…

Recessed Rubber Bumpers for Kitchen Appliance’s: Polyethylene / Cutting boards / Microwaves

Kitchen appliances are a common staple of homes and offices. However, they can still scratch and drag across surfaces leaving marks and mess. With Budwig’s patented rubber bumpers, your products are guaranteed to be more durable and well-kept. Our feet use a combination of thermoplastic rubber or polyethylene that are…

Understanding the Material We Use for Our Plastic Bumpers

Heavy-Duty Rubber Bumpers for All Applications

Rubber bumpers may seem like modest components—but in reality, they perform critical functions in machines, furniture, electronic equipment and more. At Budwig Molded Products, we manufacture heavy-duty rubber bumpers that are built to last across a wide variety of uses. Because they’re produced in a broad range of shapes, sizes…

Understanding Durometer: Measuring the Hardness of Rubber Feet

When it comes to designing and manufacturing rubber bumpers or feet, understanding durometer is essential. Durometer is one of the most common ways to measure the hardness of a material, particularly for polymers, elastomers, and rubbers. It plays a critical role in determining how a product performs under pressure,…

Reliable Rubber Bumpers for Heaters: Built to Withstand Winter

As the winter season sets in, heating units of all types are working overtime to keep homes, offices, and industrial spaces comfortable. But one often overlooked component that contributes to their performance and longevity is the rubber bumper. Designed to absorb vibration, prevent slipping, and protect surfaces, high-quality bumpers are…

Budwig Company

Budwig Company Inc. has been designing and manufacturing proprietary injection molded thermoplastic products since 1965. We are not a distributor and only sell what we manufacture at our San Diego, California facility.

Specialty - Rubber Bumpers

Budwig specializes in TPR (thermoplastic rubber) rubber bumpers, which are used in a variety of applications in the electronics, security, medical, and consumer products and more. Budwig rubber bumpers are available in various shapes & sizes.

Facility Capabilities

Being a plastic product development and marketing facility we have the capacity to perform almost all requirements in-house: Product design, mold making, injection molding, assembly, testing and packaging. Give us a call for your project needs.

We sell only what we manufacture at our facility in San Diego, California.

We sell only what we manufacture at our facility in San Diego, California.